The APEX A rigid ultralightweight manual wheelchair is no exception. In this blog, we will explore the unique features of this ultralight aluminum frame, discuss its advantages, and offer user perspective.

The APEX A (A stands for Aluminum) is a minimalist cantilever frame that offers flexibility while maintaining rigidity for the most optimal performance. We utilize a unique aluminum alloy combined with carbon fiber features that give rise to the wheelchair’s lightweight construction. This results in easier maneuverability and greater responsiveness for the user, maximizing their propulsion efficiency and minimizing risk of upper extremity overuse or injury.

The engineering idea behind the APEX C, our carbon fiber frame (C stands for carbon). With the APEX A, the goal was to reach a larger audience and offer a more affordable wheelchair frame, specifically to users with limited funding.

“The APEX A is not only more affordable, it is also more rigid [compared to the APEX C], which makes the frame more responsive to the user. This may be a desired feature for certain customers. Additionally, it is highly customizable and has all the same adjustments as the carbon fiber frame.” - Pierre Luc Savard, Product Development Engineering Manager, Motion Composites

The unique manufacturing process of our aluminum alloy allows for the APEX A to be lightweight, yet durable to maximize its overall performance. We use a technique called triple-butting, which allows for thinner walls of tubing that create a strong yet lightweight frame. Weighing only 0.9 lb. more than our carbon frame, the APEX A provides a lightweight solution even for the most active and dynamic user. In contrast, it is typical to see up to a 4 lbs. difference between aluminum and carbon fiber frames.

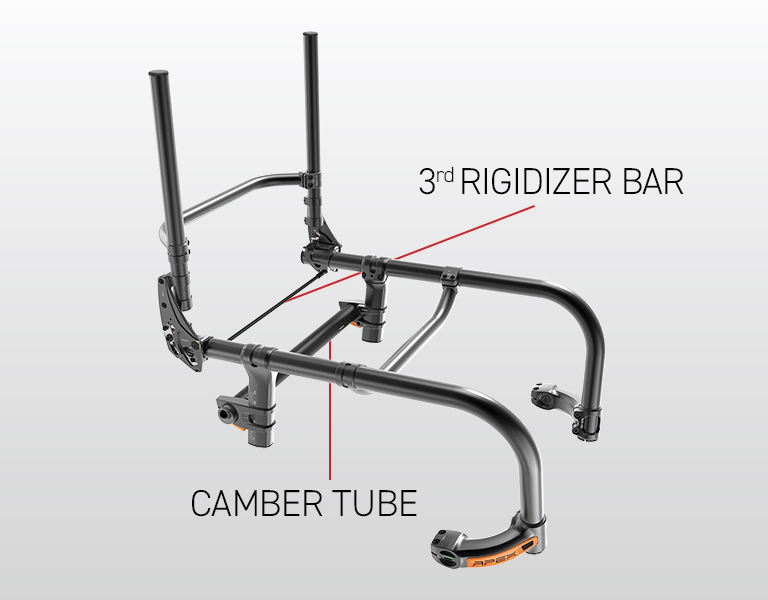

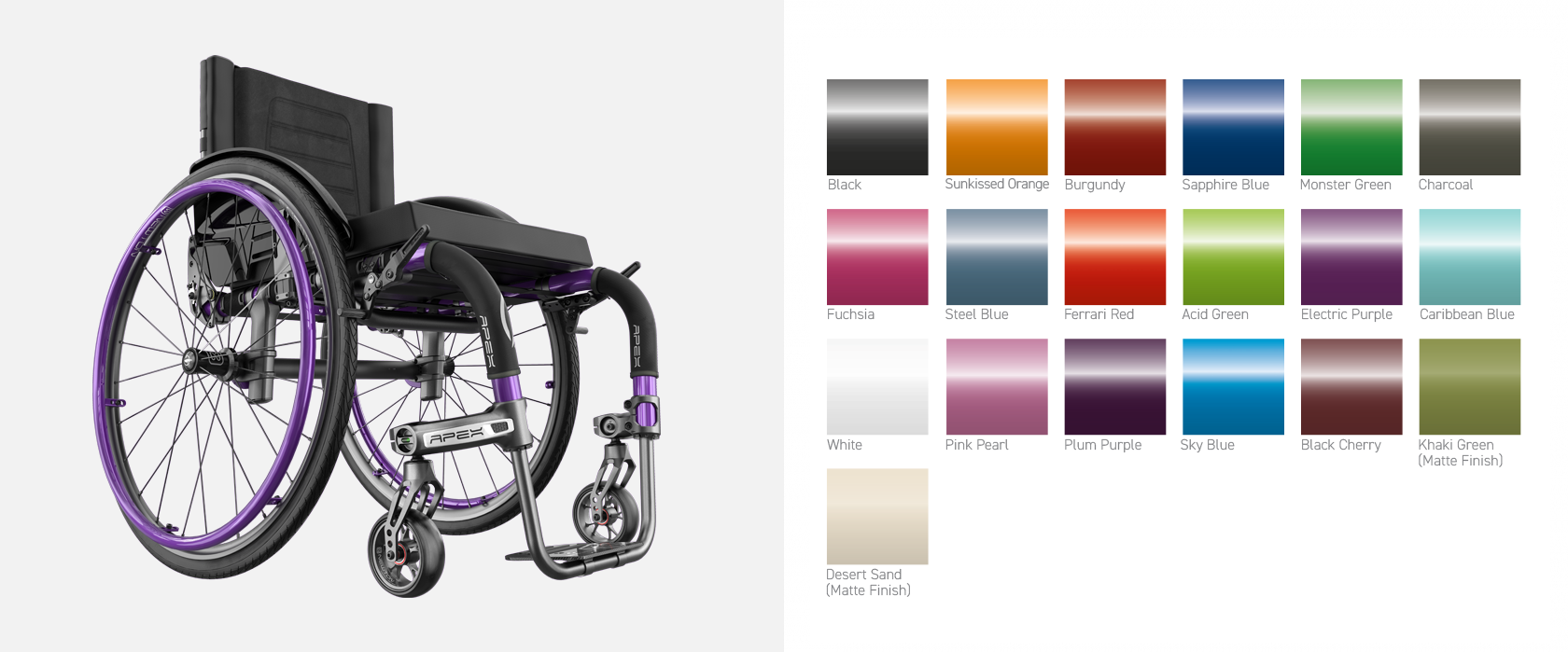

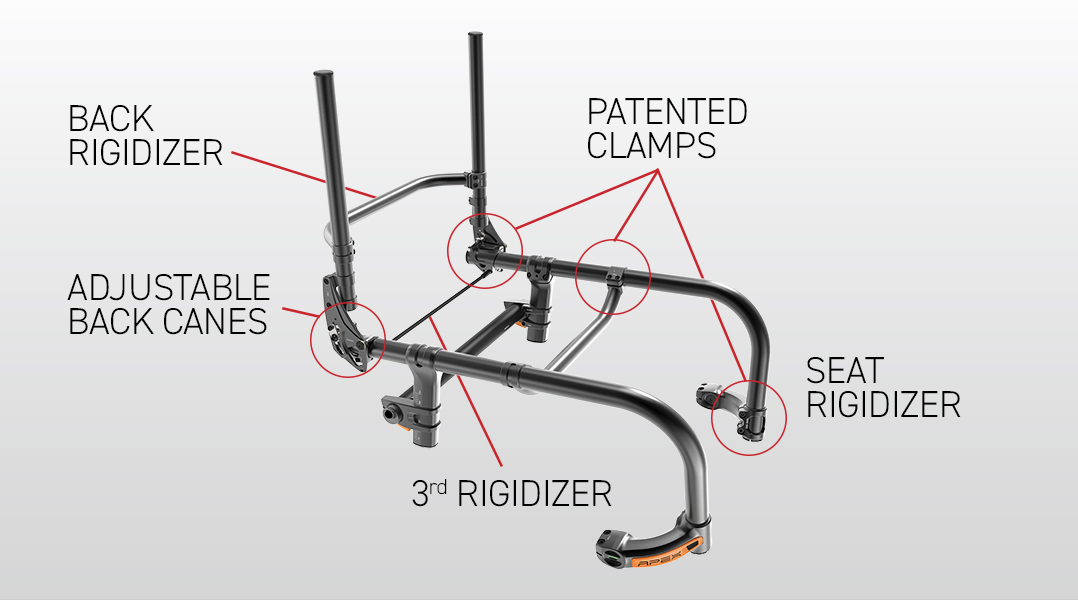

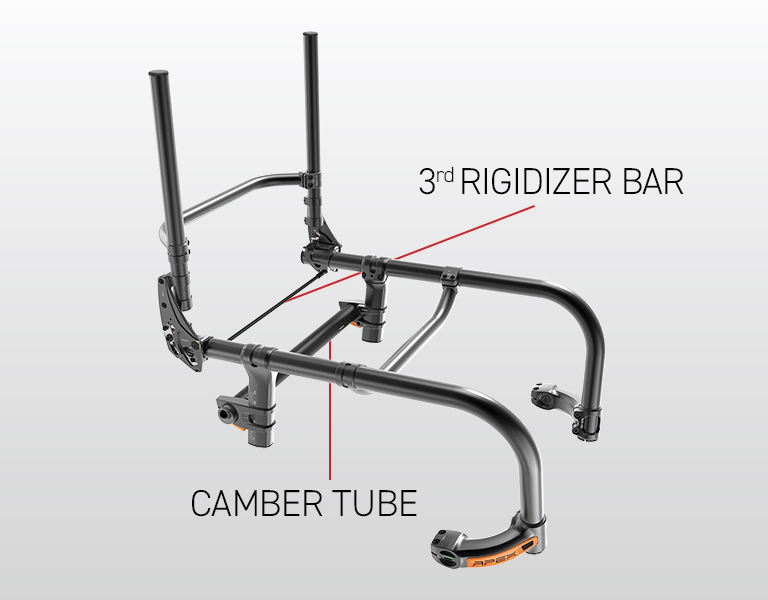

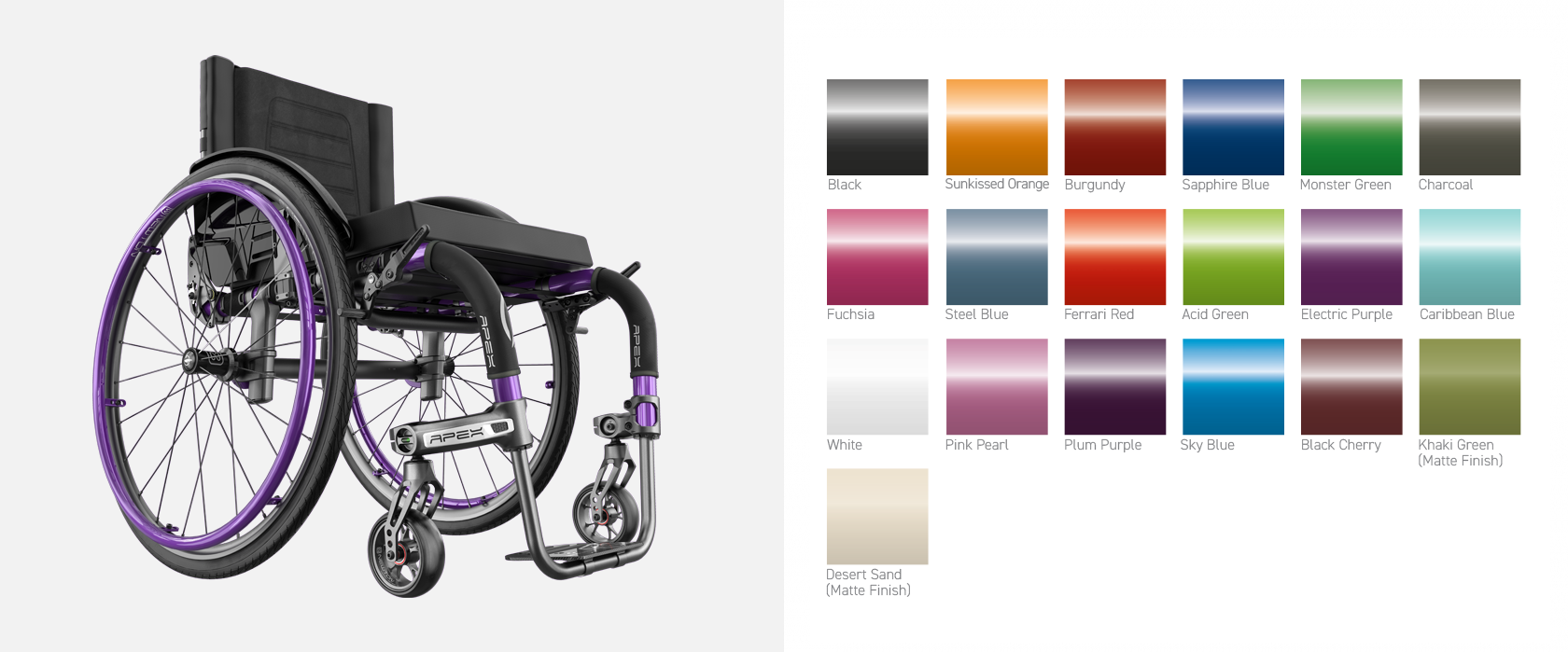

Additionally, the carbon fiber features that come standard on our aluminum frames include the camber tube and extra rigidizer bar. The combination of the lightweight aluminum frame with the carbon features make the wheelchair more responsive, which helps synchronize the wheelchair performance with the user’s functional needs. Also, you now have a choice of 19 colors for the frame paint, as well as 7 accent colors to personalize your APEX A.

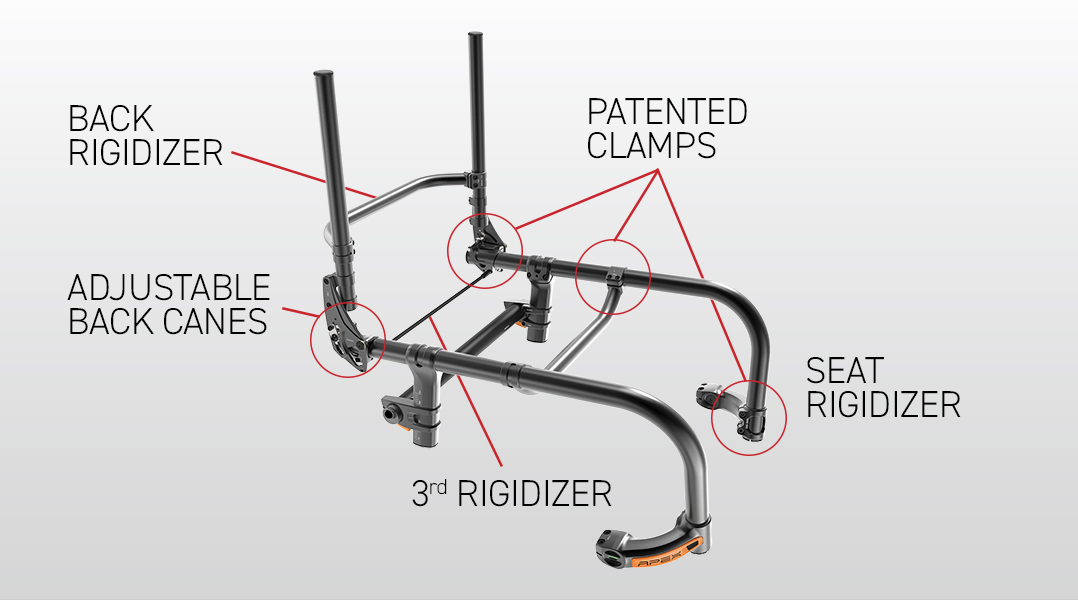

All other features and adjustability on the APEX A are identical to those on the APEX C carbon frame. Our patented clamping system facilitates secure attachment of the back and seat rigidizer bars and the casters to the frame without the need to drill holes into the frame. This minimizes the risk of breakage and weakening of the frame structure. The three rigidizer bars mounted under the seat, behind the back, and just under the rear of the seat sling promote frame stability while allowing for front frame flexibility. The rear adjustable axle features laser-etched markings for quick and efficient vertical and horizontal adjustment in the field. The seamless design of the rear axle allows infinite adjustability to the center of gravity and rear seat to floor height, accommodating even the most sensitive configuration settings. Our fully adjustable casters feature a bubble level gauge, which ensures that the casters are set square to the ground. The back canes and the back support hardware allow for seat-to-back angle adjustments to help facilitate optimal postural alignment and stability. Lastly, the frame length can be customized to the user’s needs to allow for stability and safety where needed.

“ … the adjustability in the hardware for my NXT backrest has been crucial to my safety and comfort as my spinal issues and pain progress. We are constantly micro adjusting my backrest angles and I’m so grateful for it.” Ali Kadet, APEX A User

Bubble Level (Available in the APEX A, APEX C and VELOCE wheelchair models)

Bubble Level (Available in the APEX A, APEX C and VELOCE wheelchair models)

Rear Adjustable Axle

Rear Adjustable Axle

Our Newton wheelchair components help keep the total weight of our APEX A as light as possible. We offer a variety of lightweight components to maximize propulsion efficiency, the equipment’s functionality, and safety for the user. These include the front casters, handrims, wheel locks, footplates, and rear wheels. Additionally, we offer a backpack and a multi-purpose pouch specifically designed to fit our wheelchairs and carry the user’s belongings without compromising their function.

“Overall, the APEX combines lightweight agility with just enough built-in flex to keep rides comfortable, all while offering a level of adjustability and finish detail that makes it truly feel like a custom build right out of the box. If you’re looking for a frame that performs across a range of daily activities indoors, outdoors, quick errands or long pushes it’s hard to beat what APEX brings to the table.” Wahbeh Nuseibeh, APEX A User

Because of the cantilever frame design and our manufacturing techniques, the width and depth of the APEX A frame cannot be ‘grown’ in the field. However, Motion Composites offers a frame replacement service through our EVO Rigid Program. This program is designed to accommodate changes in the user’s health condition or function that would require a different size of the wheelchair frame. The EVO Rigid Program will replace the user’s existing frame for a newly fitted, individually adjusted frame to match the client’s positional and functional needs. What’s more, the new frame is shipped directly to the user’s dealership location so that they can keep their existing frame until the replacement arrives.

The APEX A is built through cutting-edge technology and engineering. Every wheelchair is made with exceptional quality, individualized care, flawless design, and attractive aesthetics to meet the unique needs of each user. Motion Composites creates all of their products with the user in mind to help maximize the individual’s quality of life, nurture a sense of freedom and empower their choices in the world of wheeled mobility.

“Truly indestructible and lightweight, unlike any other product on the market.” Wahbeh Nuseibeh, APEX A User

“My overall experience has certainly been positive and it is the key to my comfort and quality of life.” Ali Kadet, APEX A User

Bubble Level (Available in the APEX A, APEX C and VELOCE wheelchair models)

Bubble Level (Available in the APEX A, APEX C and VELOCE wheelchair models) Rear Adjustable Axle

Rear Adjustable Axle