Exploring the clinical and functional benefits of carbon fiber for manual wheelchair users.

Carbon Fiber: Reshaping Mobility

CARBON FIBER PROPERTIES AND CLINICAL CONNECTION FOR WHEELCHAIR USERS

Carbon fiber

A brief history

First discovered in 1958, carbon fiber has reshaped every industry from high end sporting goods to aerospace, and now wheelchairs. The National Academy of Engineering named composite materials, including carbon fiber, one of the 20 greatest engineering achievements of the 20th century. What is carbon fiber, what can it do for me clinically, and why use it to build a manual wheelchair? The answers to these questions are why carbon fiber and its limitless applications should be your first choice in manual mobility.

What is Carbon Fiber?

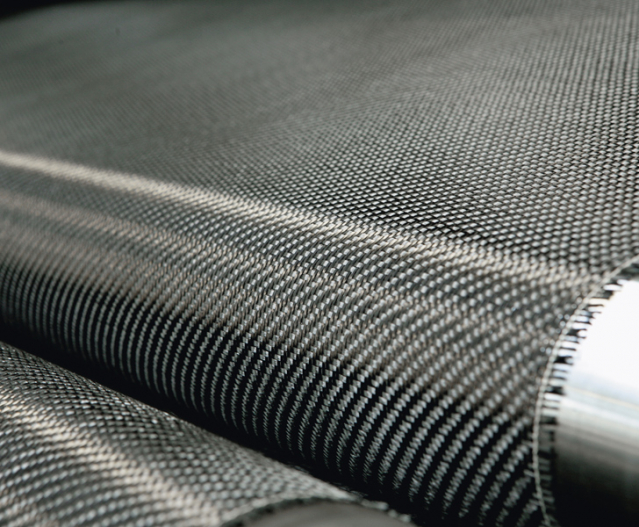

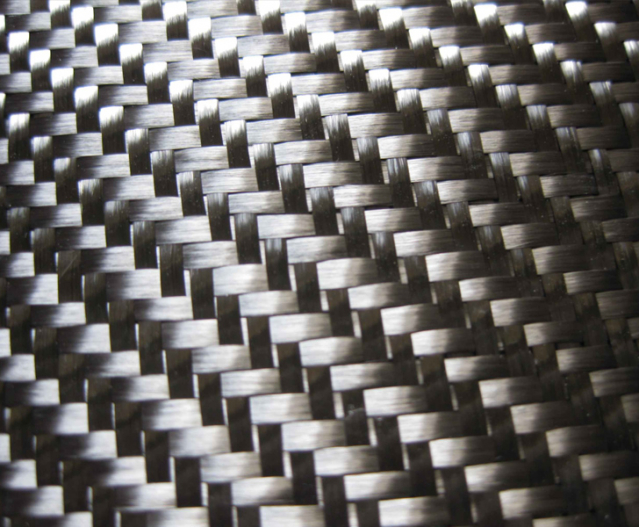

Carbon fibers are filaments smaller than a human hair consisting mainly of carbon atoms. Several thousand filaments are bundled and used on their own or woven into a fabric.

What is Composite Material?

According to the National Academy of Engineering, a composite material is a combination of two or more materials differing in form or composition that retain their identities. Combining carbon fiber fabric with a matrix of plastic resin forms one example of a composite. This strong, light composite material, commonly referred to as carbon fiber, is used to manufacture vehicles, sporting goods, and Motion Composites wheelchairs. There are various manufacturing methods and proprietary carbon fiber composites used across this wide range of industries. Not all carbon fiber products are designed to meet the same needs, withstand the same forces, or provide the same longevity. Carbon fiber products can differ as much as an aluminum soda can and an aluminum wheelchair. The construction is just as important as the material science. The following properties explain why Motion Composites uses carbon fiber in the mobility marketplace.

Carbon fiber properties

High specific strength

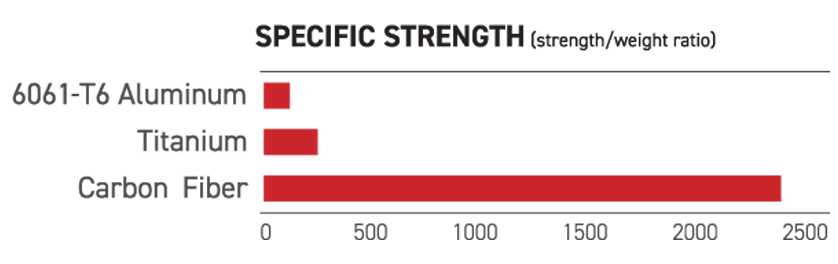

When comparing manual wheelchair transport and configured weights, it is important to consider the strength of the wheelchair. In engineering, it is common to measure the benefit of a material in terms of strength to weight ratio, or specific strength. Specific strength is defined as a material’s strength divided by its density (Bhatt, 2017). This strength is expressed in newton meters per kilogram. Carbon fiber has a significantly higher specific strength or strength to weight ratio compared to the leading wheelchair materials used in the industry today. According to figure 1, 1 kilogram of carbon fiber, approximately 2.2 lbs, would be able to withstand at least 7 times the force of titanium and 18 times the force of 6000 series aluminum. Pound for pound, carbon fiber is significantly stronger than any metal used in the wheelchair industry today. That is undeniable material science.

Figure 1

Exceptional Durability

Carbon fiber has superior fatigue resistance compared to metals. This means that components made of carbon fiber will resist the repetitive stress of everyday use longer. Motion Composites’ carbon fiber wheelchairs withstood double the minimum number of cycles required on the NSI/RESNA* fatigue strength test of durability.

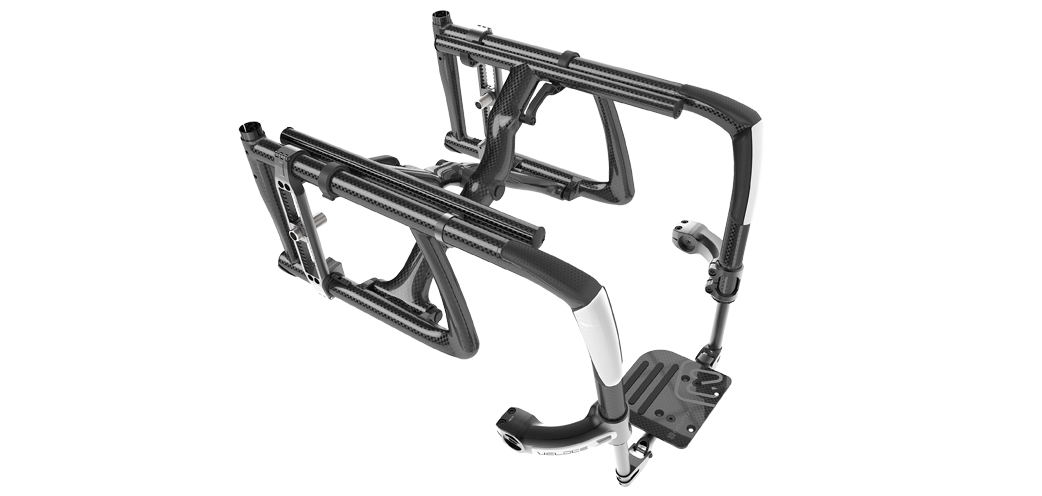

No Welding

Since carbon fiber is not a metal, it is not limited in the shapes, bends, and angles that can be achieved. Carbon fiber is not welded but rather molded into the desired shape. As a result, there is no loss of integrity in the carbon fiber at an aggressive bend in the frame. Metal, however, weakens as it bends. Abrupt changes in direction require a welding of two pieces to achieve aggressive angles or a gradual bending over the length of the tube. During the welding process, the heat treatment of metals can lower the strength of the frame considerably, up to 40% at weld points. For the strongest frame possible, through every inch of tubing, regardless of shape, carbon fiber is the clear choice.

Vibration Damping

(Fan, 2018). Wheelchair users also experience long-term exposure to low-frequency vibration from using a manual wheelchair. The materials used in the wheelchair’s construction can damp the vibration transmitted to the user. Damping is the restraining of vibratory motion by dissipation of energy (Britannica, 2020). Effectively, damping is turning down the volume on the vibration. Metals, uninhibited by damping properties, ring like a wind chime when struck whereas carbon fiber composites produce a thud. Carbon fiber does not vibrate to the extent of metals. The vibration damping property of carbon fiber in Motion Composites wheelchairs reduces the vibration transmitted to the user’s spine. In turn, our clients report decreased back pain, decreased neurogenic pain down the legs, and reduced fatigue. The vibration damping property of carbon fiber allows our clients to go farther than ever before.

Low Thermal Expansion

Thermal expansion is the increase in space a material occupies as its temperature increases (Britannica, 2017). A material with a positive coefficient of thermal expansion (CTE), such as titanium, steel, or aluminum, changes size with extreme temperature changes. Over time, expanding and contracting will decrease the integrity of the frame and its components. Carbon fiber has a negative CTE that approaches zero when combined with a matrix, such as in our composites (Bhatt, 2017). Our composite material’s exceptionally low thermal expansion results in insignificant expansion or contraction in extreme temperatures. The low thermal expansion of carbon fiber and composite materials is an exceptional property for a wheelchair frame to have.

Corrosion Resistance

Corrosion is the gradual destruction of a material due to exposure to the environment. Corrosion is apparent in most metal wheelchair frames and associated hardware. Carbon fiber and the resulting composites used in Motion Composites carbon fiber wheelchairs are highly corrosion resistant (Bhatt, 2017). Our carbon fiber wheelchair frames withstand the elements for the long haul.

The Clinical Advantage

Motion Composites wheelchairs are not just beautifully designed, state-of-the-art products, our wheelchairs change lives. We understand manual wheelchairs are a vital piece of medical equipment in the lives of our clients. Through material science and quality construction, we bring viable, durable, realistic applications of carbon fiber to the wheelchair industry.

Worldwide, our clients benefit from the high-specific strength, exceptional durability, and absence of weld points with each of our carbon fiber frame wheelchairs. Carbon fiber allows for the strongest wheelchairs at the lightest weights. Clinical evidence supports ultra-lightweight wheelchairs contribute to upper limb function preservation, easier propulsion, and reduced equipment abandonment (Boninger, 2005). Ultra-lightweight wheelchairs reduce the burden on users and caregivers when transporting the wheelchair in and out of the car, lifting up stairs, or when traveling. Carbon fiber’s exceptional durability translates to a more reliable and safer wheelchair requiring fewer repairs than the leading metal wheelchair. Less maintenance on a higher quality product equates to superior cost effectiveness over the lifetime of the chair, beneficial to end user and funding agencies alike. Nearly 40% of wheelchair users report abandoning equipment, especially low performing equipment (Phillips, 1993). Factors listed as affecting performance included safety and durability. Choose safer, more durable carbon fiber for better outcomes. The elimination of joints or welds means a solid, seamless finish which is preferred for cleaning and infection control, especially in a multi-user environment. Without joints, drilling, and bolt assembly or welding, our one piece (monocoque) frame means less movement within the frame, increased propulsion efficiency, and further weight savings and durability.

Exceptional vibration damping, low thermal expansion, and corrosion resistance of carbon fiber and our resulting composite material yield clinical benefits in any environment adventure takes our clients. Bumpy roads, moisture, and extreme temperatures are no match for the resilient frame material. The vibration damping property of carbon fiber in Motion Composites wheelchairs reduces detrimental vibration transmitted to the user’s spine. Our clients happily report decreased back pain, reduced neurogenic pain down the legs, and less fatigue. Less expansion and contraction of the wheelchair materials equates to consistent interaction between the frame components ensuring a smooth comfortable ride, regardless of the elements. Corrosion resistance in carbon fiber wheelchairs further allows for a durable and cost effective mobility solution over time.

Through exceptional material science and quality construction, Motion Composites continues to introduce innovative, clinically beneficial, carbon fiber mobility solutions to market. Our commitment remains, “to lead the evolution of mobility for better living.”

Carbon fiber myths

Myth #1

Performs poorly in cold temperatures

Carbon fiber components are used extensively in aircraft and satellites, which are exposed to temperatures that range from superheated to near absolute zero. Carbon fiber’s low thermal expansion properties make it ideal for extreme temperature changes.

Myth #2

Breaks or chips easily

Carbon fiber technology has greatly improved over the last decade. It is now used in high-impact applications such as baseball bats.

The Motion Composites design team worked for three years to determine the best fiber alignment for durability, lightness and propulsion efficiency.

Myth #3

Catastrophic damage

Other carbon fiber wheelchairs and sporting goods (bikes, hockey sticks, etc.) have had a reputation for catastrophic damage that render the product unusable. The strength of a carbon fiber component is a function of its design. Since a layer of carbon fiber is strong only in one direction, some carbon fiber products (e.g., hockey sticks) are designed to flex and are therefore more susceptible to breakage. Depending on how the carbon fiber is laid and aligned, extraordinary strength in torsion, compression and flexion can be achieved.

Still have doubts about carbon fiber?

Click here to read about our lifetime carbon fiber warranty

Click here to check the Carbon Fiber Funding Guide

Check out our blogs about carbon fiber:

Carbon fiber clinical rationale: A solution for upper extremity preservation

Carbon Fiber 101: Everything you need to know about it

Wheelchairs: Carbon Fiber versus Aluminum

Make sure to read the clinical rationale behind carbon fiber right here!

References

- Bhatt, P., & Goe, A. (2017). Carbon Fibres: Production, Properties and Potential Use. Material Science Research India, 14(1), 52–57. https://doi.org/10.13005/msri/140109

- Boninger ML, Koontz AM, Sisto SA, Dyson-Hudson TA, Chang M, Price R et al. Pushrim biomechanics and injury prevention in spinal cord injury: Recommendations based on CULP-SCI investigations. J Rehabil Res Dev 2005;42(3 Suppl 1):9–20.

- Britannica, T. Editors of Encyclopaedia (2017, August 4). Thermal expansion. Encyclopedia Britannica. https://www.britannica.com/science/thermal-expansion

- Britannica, T. Editors of Encyclopaedia (2020, May 27). Damping. Encyclopedia Britannica. https://www.britannica.com/science/damping

- Cowan RE, Nash MS, Collinger JL, Koontz AM & Bonninger ML (2009). Impact of surface type, wheelchair weight and axle position on wheelchair propulsion by novice older adults. Archives of Physical Medicine and Rehabilitation, 90(7): 1076–1083.

- Fan, R., Liu, J., Li, Y., Liu, J., & Gao, J. (2018). Finite Element Investigation of the Effects of the Low-Frequency Vibration Generated by Vehicle Driving on the Human Lumbar Mechanical Properties. BioMed Research International, 2018, 1–9. https://doi.org/10.1155/2018/7962414

- Mann WC, Goodall S, Justiss MD, Tomita M. Dissatisfaction and nonuse of assistive devices among frail elders. Assist Technol 2002;14:130–9. [PubMed: 14651251]

- Paralysed Veterans of America Consortium for Spinal Cord Medicine (2005). “Preservation of upper limb function following spinal cord injury: A clinical guideline for health-care professionals.” Journal of Spinal Cord Medicine, 28(5):434–470.

- Phillips, B., & Zhao, H. (1993). Predictors of assistive technology abandonment. Assistive Technology, 5(1), 36–45.

- Rehabilitation Engineering & Assistive Technology Society of North America (RESNA). 2012. Position on the Application of Ultralight Manual Wheelchairs [position paper]. Retrieved from: RESNA: www.resna.org/resources/position_papers.dot. (2011). Position on the Application of Ultralight Manual Wheelchairs [position paper].

- Requejo P, Mulroy, Haubert, et al. Evidence-Based Strategies to Preserve Shoulder Function in Manual Wheelchair Users with Spinal Cord Injury. Top Spinal Cord Injury Rehabilitation. 2008; 13(4): 86–119.